This Schaeffler service is new to the market and allows equipment operators to have a predictive maintenance solution that offers a long-term vision of the future before it is registered or detected possible irregularities in engine systems.

ETAuto | Jul 25, 2016, 12.53 PM IST

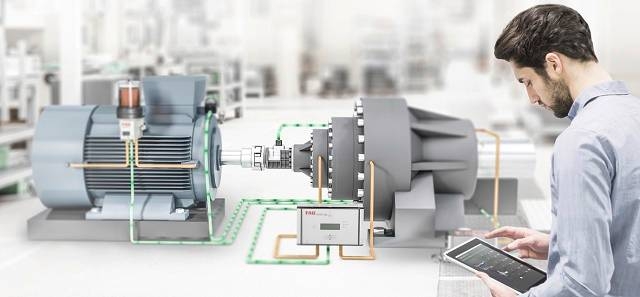

NEW DELHI: German auto component manufacturer Schaeffler has presented a new digital service in 2016 Hanover Fair which helps to calculate the remainder of the nominal lifetime of the bearings based on the actual load spectrum recorded during operation. This Schaeffler service is new to the market and allows equipment operators to have a predictive maintenance solution that offers a long-term vision of the future before it is registered or detected possible irregularities in engine systems.

The remainder of the nominal life time of each bearing a machine or a system is obtained by subtracting the current period of operation of the new service life, which is constantly recalculated on predefined intervals. The client can check the remainder of the nominal lifetime of each of bearings equipment in a device adapted for connection to the Internet. The system will send an alert by email when detect that, according to the calculation of the actual load spectrum, the bearing position will reach the end of the nominal lifetime after "x" hours or weeks of operation.

The comparison of the remaining time period nominal lifetime of the bearings in a production facility with the next scheduled maintenance tasks allows the plant operator to control the production process, preventing fail bearings before reaching the next interval provided for maintenance. If the bearing is not replaced last the remainder of the lifetime, the occurrence of a failure is imminent. The combination of this solution with the Condition Monitoring FAG SmartCheck system allows for a previous alarm message in case of irregularities, automatically decreasing the alarm limits of the SmartCheck system after the expiry of the remainder of the lifetime. Accordingly, machine operators and maintenance personnel have more time to implement the appropriate maintenance action.

The constant calculation of the remainder of the nominal lifetime of the bearings and linear guides, which often corresponds to the remainder of the lifetime of complete drives, allows you to program in advance the maintenance and requests for spare parts , extend maintenance intervals by adjusting the capacity utilization of the machines and increase the use of individual shafts and complete machines until the next maintenance interval.